|

Shanghai Jiasheng Powder Metallurgy Co., Ltd.

|

High quality Powder metallurgy

| Payment Terms: | T/T,WU,Paypal |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

powder blending,ompacting, and sintering. Compacting is generally performed at room temperature

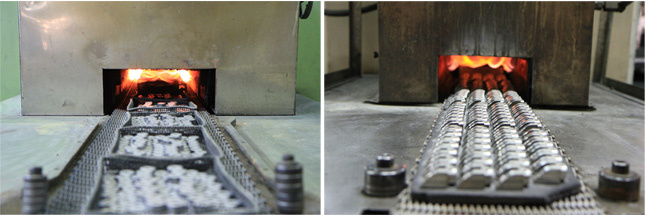

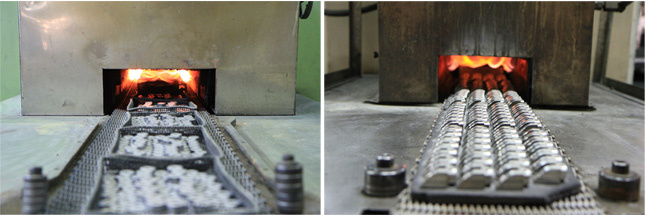

Powder Metallurgy

Powder Metallurgy, Powder Metal and/or PM High Speed Steels are alternatives to conventional steels since they have properties such as high hardness and toughness that cannot be attained in high speed steels that are produced through conventional methods. Steel grades with high temperature strength, high wear resistance and good toughness properties are necessary for today's applications. Powder Metallurgy is the process by which steel is being made to meet these needs by blending fine powdered materials, pressing them into a desired shape or form (compacting), and then heating the compressed material in a controlled atmosphere to bond the material (sintering).

The powder metallurgy process generally consists of four basic steps: powder manufacture, powder blending,ompacting, and sintering. Compacting is generally performed at room temperature, and the elevated-temperature process of sintering is usually conducted at atmospheric pressure. Optional secondary processing often follows to obtain special properties or enhanced precision. In Powder Metal steels, very small and hard alloy carbides greatly increase the wear resistance, and at the same time the ductility, in all directions. This is in contrast to conventionally produced steel where increased ductility can only be gained at the expense of reduced wear resistance or hardness.

The advantage of powder metallurgy:

Eliminate or reduce the secondary operation.

Eliminate or reduce the cutting loss.

Precise size.

Be widely used on alloy system.

Smooth surface.

Enhance the strength and abrasion resistance after heating treatment processing.

Can manufacture complicated and unique parts.

Mass production.

Providing function reliability.

Eliminate or reduce the cutting loss.

Precise size.

Be widely used on alloy system.

Smooth surface.

Enhance the strength and abrasion resistance after heating treatment processing.

Can manufacture complicated and unique parts.

Mass production.

Providing function reliability.

Compacting machines

5 tons,15tons,20tons,30tons,40tons,60tons,80tons,150tons,200tons,350tons,400tons:30

Sintering Fruances:4

Sizing macnines

20tons,30tons,35tons,60tons,110tons,200tons,400tons:10

Product Introduction:

- Motorcycle&Automobile parts:Shock absorber. Piston.

2. Electrical Home Appliance parts:Compressor. Sewing machine.

Extraction fan. The bearings of the fan

3. Agricultural Machine Compnents:Gear drive. The component of bearings

4. Business Machine Components:typewriter. Photocopier.etc.

5. Hardware components:Locks.the other components of stainless steels.

6. New Development of any new parts:

Shanghai Jiasheng Powder Metallurgy Co Ltd is the powder metallurgy parts of the professional manufacturers, with nearly twenty years of powder metallurgy products research and development experience. The company has strong technical force, complete production equipment configuration. The company covers an area of 20000 m2, the production capacity of more than 2000 tons / year.

Company's main products are: various specifications and types of copper base, iron precision oil bearing and high strength precision machinery parts, stainless steel products. Products are widely used in automobiles, motorcycles, electric tools, office equipment, medical / fitness equipment, household electrical appliances, textile machinery, environmental protection machinery, instruments and other industries.

The company obtained the ISO 9001 international quality system certificate in 2002, in 2008 through the ISO/TS 16949 certification system. The company has always been adhering to the "people-oriented, winning with quality, sincere hospitality, to survive the letter" business philosophy, and for many years was assessed in Shanghai City Administration for Industry and Commerce Shou contract re credit enterprises AAA level.

In 2012, the company's "Shanghai family Beijing Great Automotive Components Company Limited" to apply for and obtain "high-tech enterprises in Shanghai city" title.

Business philosophy: people-oriented, winning by quality, sincere hospitality, to survive the letter.

Quality policy: the quality of refinement, customer satisfaction, innovation, sustainable management.

Company's main products are: various specifications and types of copper base, iron precision oil bearing and high strength precision machinery parts, stainless steel products. Products are widely used in automobiles, motorcycles, electric tools, office equipment, medical / fitness equipment, household electrical appliances, textile machinery, environmental protection machinery, instruments and other industries.

The company obtained the ISO 9001 international quality system certificate in 2002, in 2008 through the ISO/TS 16949 certification system. The company has always been adhering to the "people-oriented, winning with quality, sincere hospitality, to survive the letter" business philosophy, and for many years was assessed in Shanghai City Administration for Industry and Commerce Shou contract re credit enterprises AAA level.

In 2012, the company's "Shanghai family Beijing Great Automotive Components Company Limited" to apply for and obtain "high-tech enterprises in Shanghai city" title.

Business philosophy: people-oriented, winning by quality, sincere hospitality, to survive the letter.

Quality policy: the quality of refinement, customer satisfaction, innovation, sustainable management.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Powder Metallurgy

Powder Metallurgy Part

High Quality Bearing

High Quality Oil

High Quality Belts

High Quality Cameras

More>>